|

Basic Information

|

||

|

Contact

|

Luo Qinghua

|

|

|

Employer

|

Beijing KIVIN New Technology Co., Ltd

|

|

|

Email

|

luoqh@jingrun-bj.com

|

|

|

Website

|

www.jingrun-bj.com

|

|

|

Brief Introduction

|

||

|

Date of Foundation: Dec. 26, 1994

Number of employees: 10-100

Annual turnover: CNY 10,000,000- CNY 50,000,000

Industry: Energy efficiency, environmental protection

|

||

|

Brief Introduction of Corporate Products & Services:

Introduction of products:

“Three-process water purification” technology: the principle of technology is to eliminate the hardness, turbidity, suspended matter and colloid matters of water through combination of micro floating oxidation method, micro electrolytic flocculation method and combinational settlement and filtration method.

(1) Micro-flotation oxidation process: Energizing the electrode plate to ionize water molecules thus generating H+ and OH-, while H2 and O2 can be generated at both positive and negative poles, which are existed as tiny bubbles with a diameter of tens of microns, and are perfect carriers to carry impurities of water up to the surface of reaction tank. Meanwhile, newly generated active [O] and hydroxyl radical [OH.] are provided with very strong oxidation ability, by which some dissolved organic matters can be oxidized in water.

(2) Micro-electrolysis flocculation process: adding alkali to adjust the pH value of raw water, and energizing the electrode plate in the reaction tank, take metallic iron, aluminum or alloy material as the electrode, Fe3+ or Al3+ will be separated out by electrolytic consumption, and then enter water, Fe(OH)3 or Al(OH)3 and other Mononuclear Hydro complexes, multi-nuclear Hydro complexes, polymers, etc. will be generated after being combined with OH- dissolved in water, the generated complexes are existed as the absorbing groups with high activity and strong absorbability; then colloidal particles, suspended matters, macromolecule organic substances and other particles will be absorbed by adsorption bridging and enmeshment action and finally settled.

(3)Sedimentation combined with filtration process: through the high load and inclined tube sedimentation tank, the large amount of flocculating constituents generated in the reaction tank will be settled in sedimentation tank, the tiny rest flocs will enter the high efficiency filtration tank, the quartz sands and anthracites in the high efficiency filtration tank are used as the filter materials to filtrate the particles in water, and reduce the water turbidity below 1NTU.

Processing effect: removal of hardness, turbidity, suspended matter and colloid matters

Remove COD at a rate up to 30%~60%

Remove oil in water at a rate up to 95%

Remove total phosphorus at a rate over 90%

Remove SiO2 at a rate over 60%

Remove heavy metal ions at a rate over 95%

JR-EDR desalination apparatus: aiming at the common problems of traditional electrodialyzer, JR-EDR has made the great improvement, taking the new compound semiconductor materials as the electrode, which are provided with strong corrosion- resistance performance, and the service life of electrode is very long, and the neutral semipermeable membrane with large aperture is adopted in the design, which is resistant to oxidation, acid and alkali, corrosion and hydrolysis, the semipermeable membrane is not easy to be blocked, and is pollution-resistant, and the service life is very long.

The process features are:

1. The membrane materials are provided with strong pollution-resistant performance, easy to be washed and recovered, the materials ask for less of inflow water quality.

2. The system backwater rate can be up to more than 75%.

3. The salt rejection rate can reach to 80%, the effluent treatment can meet the circulating water requirements.

4. Low energy consumption and operation cost. According to actual experience, when the saltiness is less than 3000mg/L, the energy consumption of water treatment per ton is 0.5-0.8 KWH/ton.

5. Less effect from agent such as anti-sludging agent, disinfectant etc. in circulating water.

High automaticity, frequent pole reversing control method is adopted to prevent the problem of concentration polarization.

6. According to the water quality, the service life is 3 to 5 years, and the cost of membrane replacement is very low.

Processing technology of refractory COD: Removing industrial polluting water by biological treatment method (good biodegradability), flocculation filtering method (refractory COD) to meet national standards of sewage discharge.

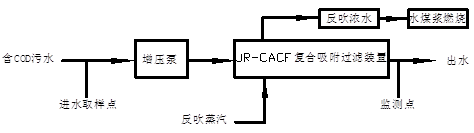

1.1.1 COD processing flow

含COD污水Sewage containing COD

增压泵Booster pump

反吹浓水Counter blowing strong water

水煤浆燃烧Water-coal-slurry combustion

JR-CACF复合吸附过滤装置JR-CACF compound adsorption and filtering device

出水Effluent

进水取样点Sampling point of inflow water

反吹蒸汽Back flushing steam

监测点Monitoring point

1.1.2 Introduction to JR-CACF equipment principle

1、 JR-CACF compound absorption and filtering equipment establishes the absorption and filtering by the filtering element, and main adsorbing material of filtering element is active carbon fiber materials, the compound carbon fiber absorption materials are provided with strong specific surface area and rich millipores, the diameter of millipore is 1nm to 4 nm. During absorption process, due to different acting forces between of absorbing medium molecules and surface molecules of adsorbent, different adsorptions such as exchange adsorption, physical adsorption and chemical adsorption are generated.

2、 Filtering element in JR-CACF compound absorption and filtering equipment is provided with strong absorbability for COD, oil and other substance, especially for the resolvable and COD which is difficult to be degraded, the filtering element is provided with better removal effect. The filtering element which is produced by the absorbent fibers with different absorbability, the removal rate for COD can be up to 50-95% and removal rate of oil can be above 90%.

3、 Filtering element in JR-CACF compound absorption and filtering equipment is provided with good performances such as high temperature resistance, acid and alkali resistance, large absorption, convenient absorption and dehydration, long service life (>3-8 year) and other performances.

4、 After filtering element of JR-CACF compound absorption and filtering equipment is saturated, desorption and regeneration can be realized by high temperature steam (>140℃), after the regeneration is finished, the performance of filtering element can be recovered. The regeneration period of filtering element depends on the water quality, a desorption and regeneration time is about 10min to 30min, the filtering cycle can be replaced, and the service life of equipment is more than 15 years.

1.1.3 JR-CACF equipment application

JR-CACF compound absorption and filtering equipment are good at COD removal in different kind of water, mainly includes:

1. Processing for sewage including COD, which is difficult to be degraded.

2. Further processing for standard discharged sewage COD.

3. Processing for COD in RO desalted strong water.

4. Processing for COD in circulating water and disposal sewage.

5. Processing for COD in various production process water.

6. Processing for oil and COD in steam condensate.

Service introduction

Beijing KIVIN New Technology Co., Ltd. makes full use of various advanced water processing technologies and rich engineering experience, to provide practical and reliable deep water processing technical solutions to customers, and make great contributions to China’s environmental protection industry by excellent technical design, project construction, installation and commissioning, technical training and after-sale services.

|

||

|

Demand int’l cooperation

|

||

|

Category of demand int’l cooperation:

1. cooperation in technology or products R&D

2. cooperation in strategic investors

3. cooperation in product market distribution

|

||

|

Brief introduction of demand int’l cooperation:

To meet the need of development, the Company wishes to seek technology or product R & D, strategic investor and product marketing cooperation. The Company sincerely welcomes sincere cooperation with the world customers with leading hi-tech strength and which desire to devote to the industry or related product to create a glorious prospect!

|

||